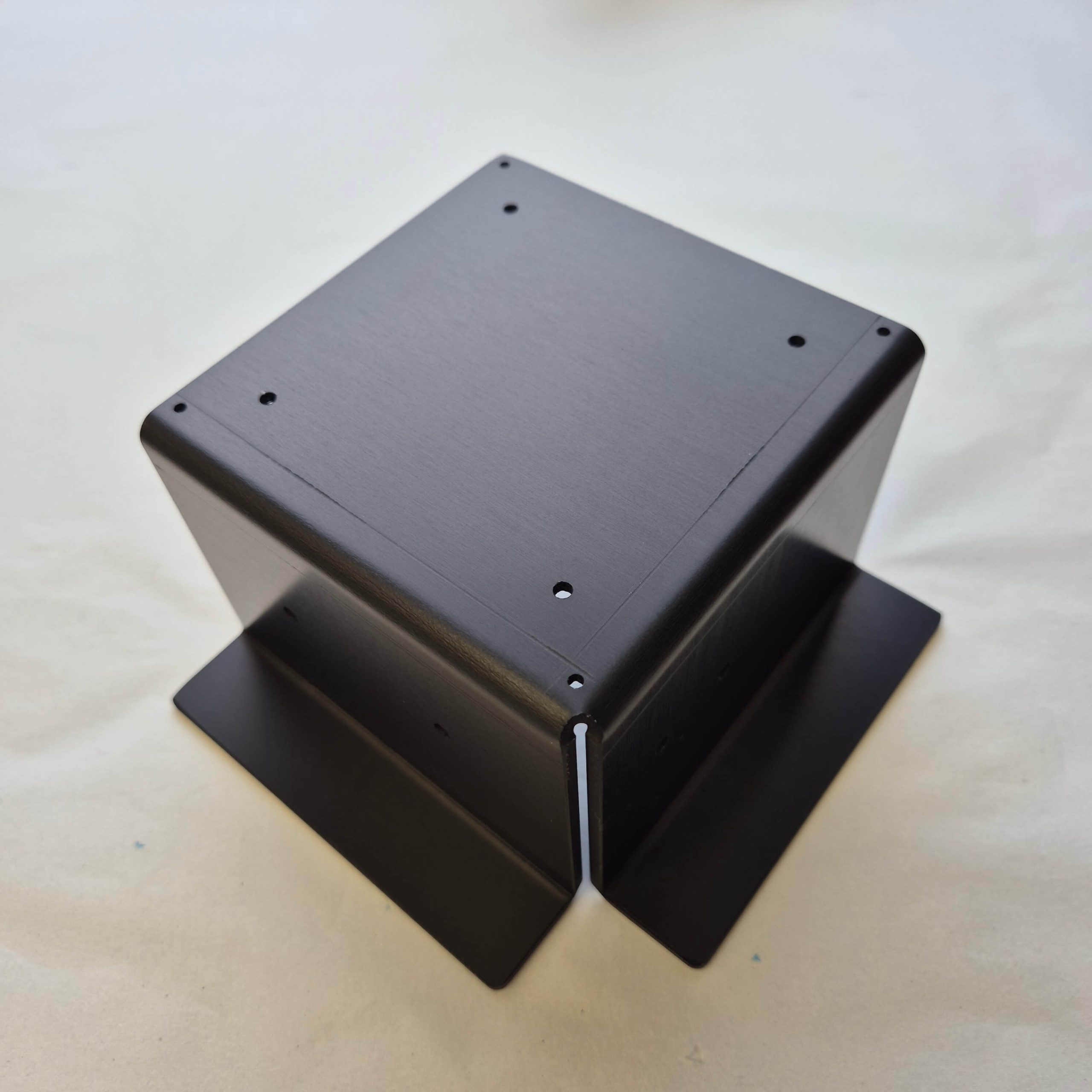

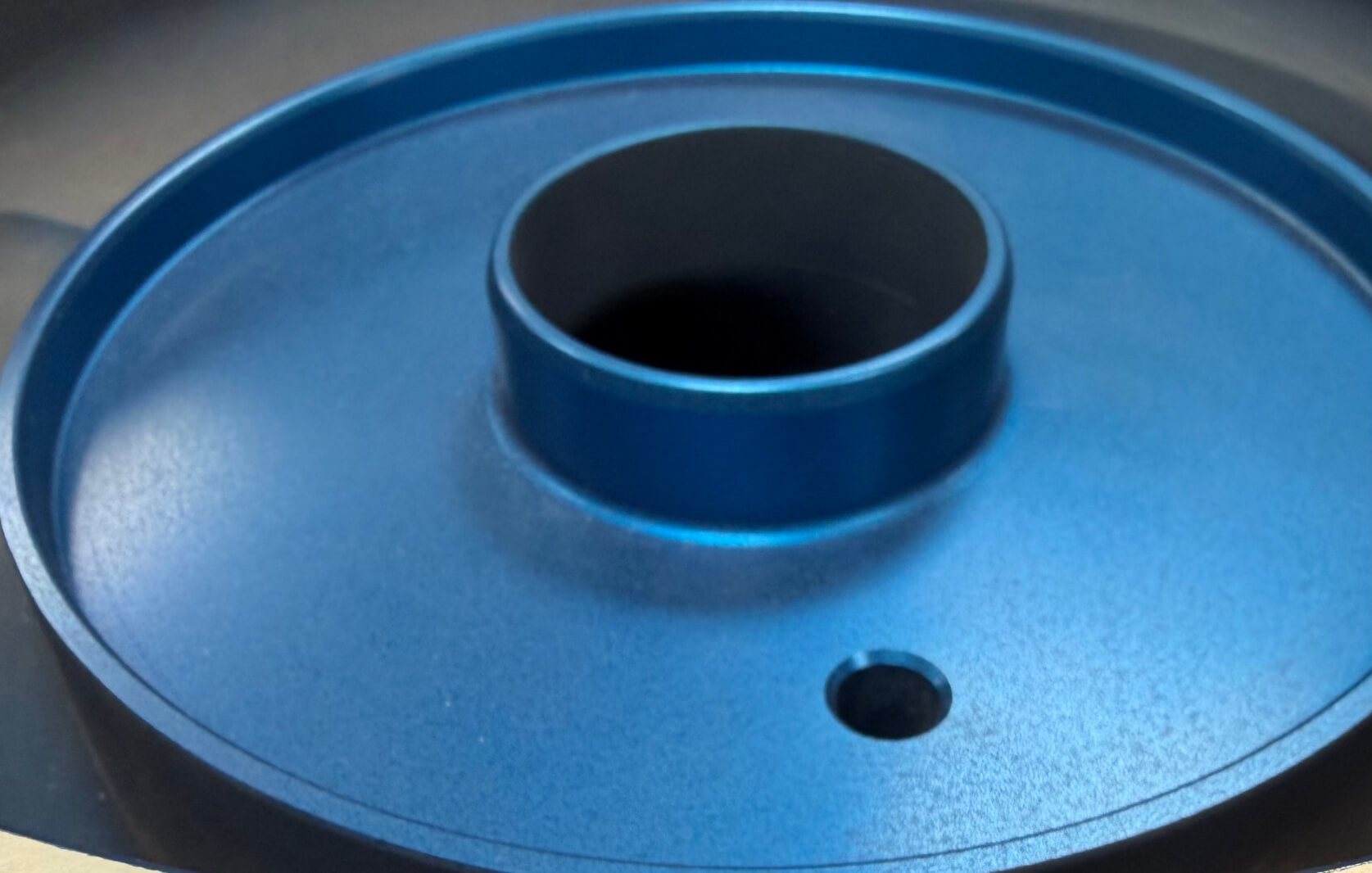

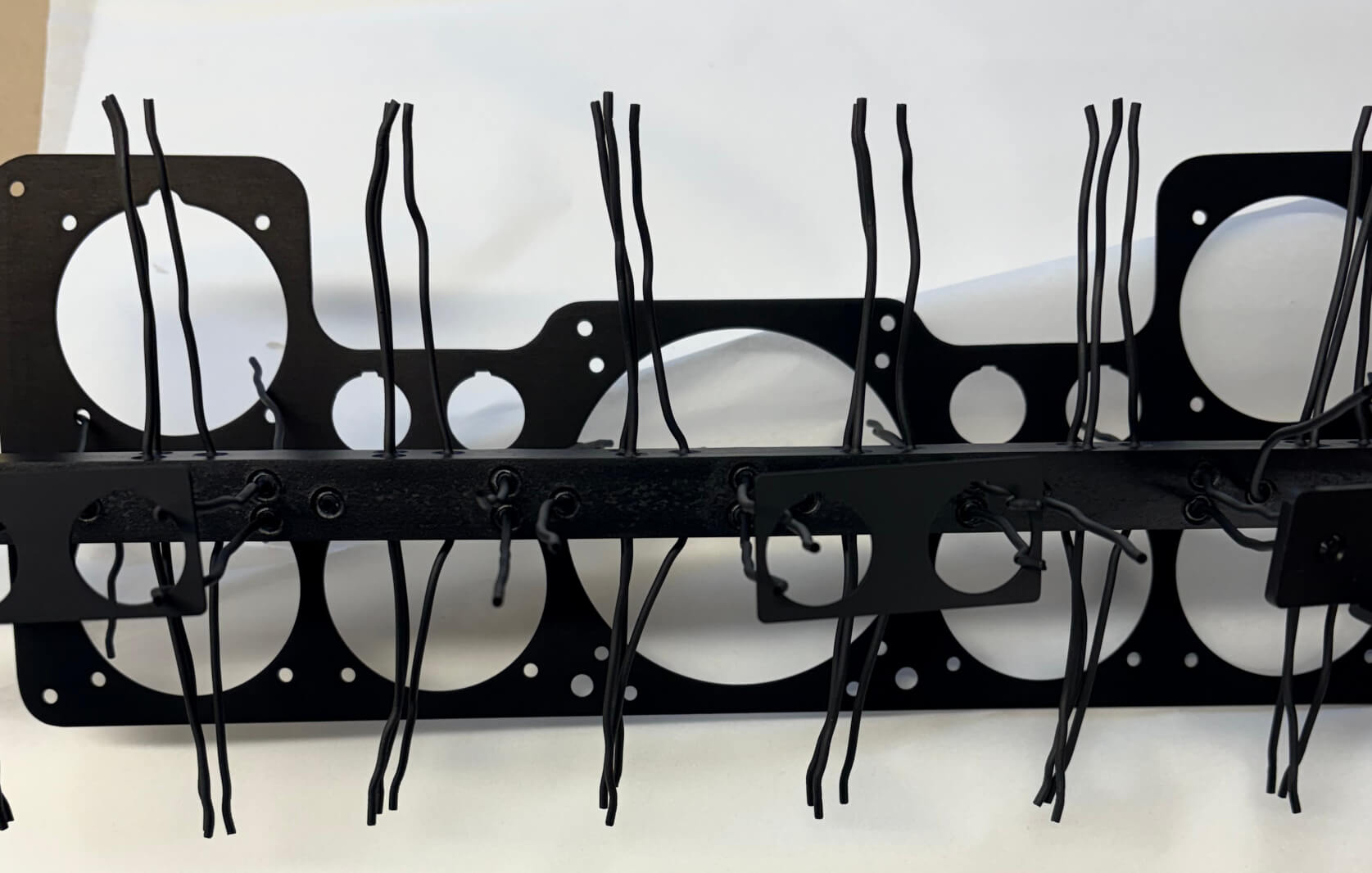

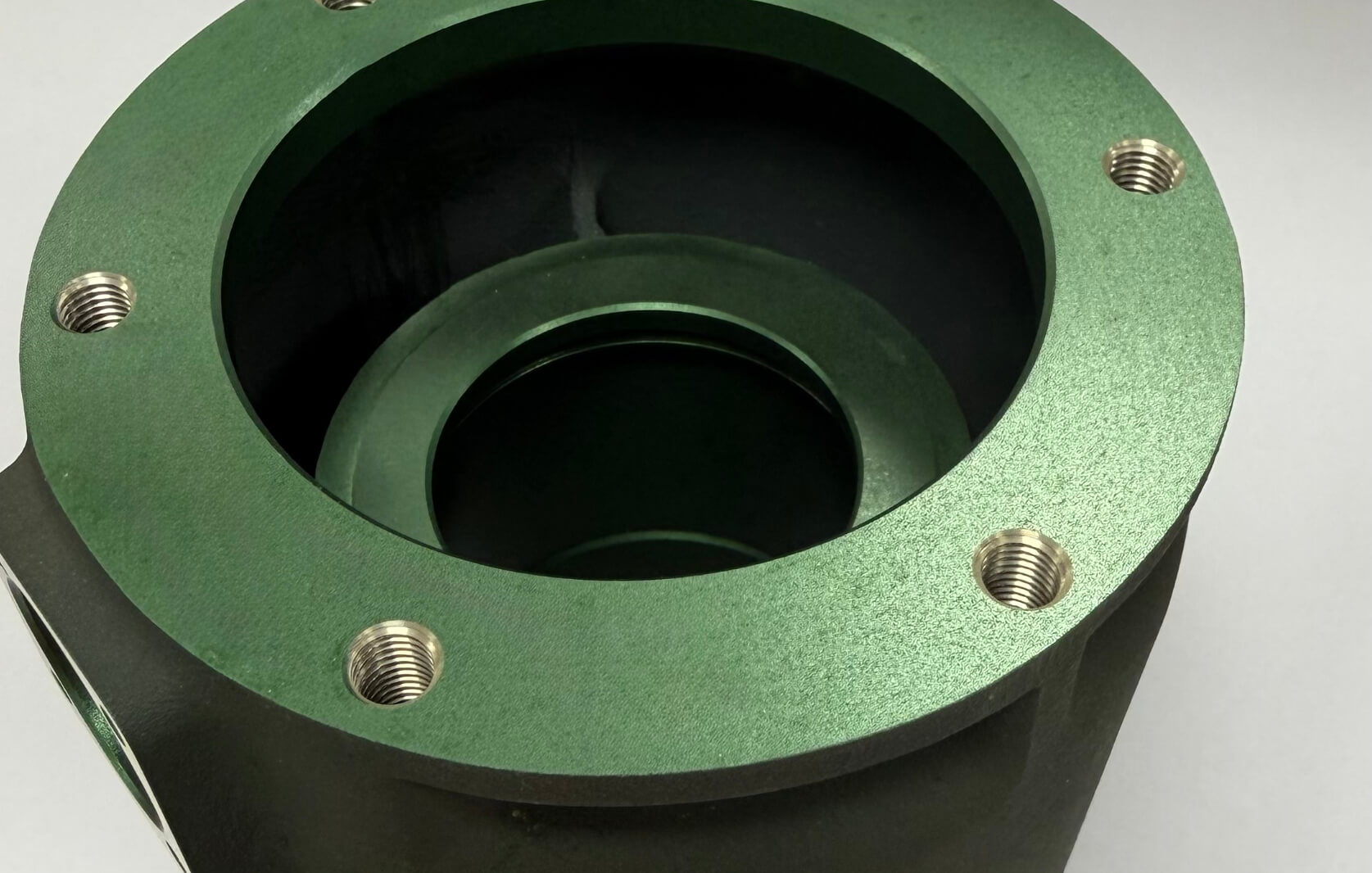

Sulphuric Anodising is an electrochemical process that converts the surface of aluminium into a durable, corrosion-resistant oxide layer. It enhances appearance, hardness, and protection while allowing coloured dyes or sealants to be added for improved performance or aesthetics.

Corrosion Protection

Creates a tough oxide film that resists wear, weathering, and chemicals.