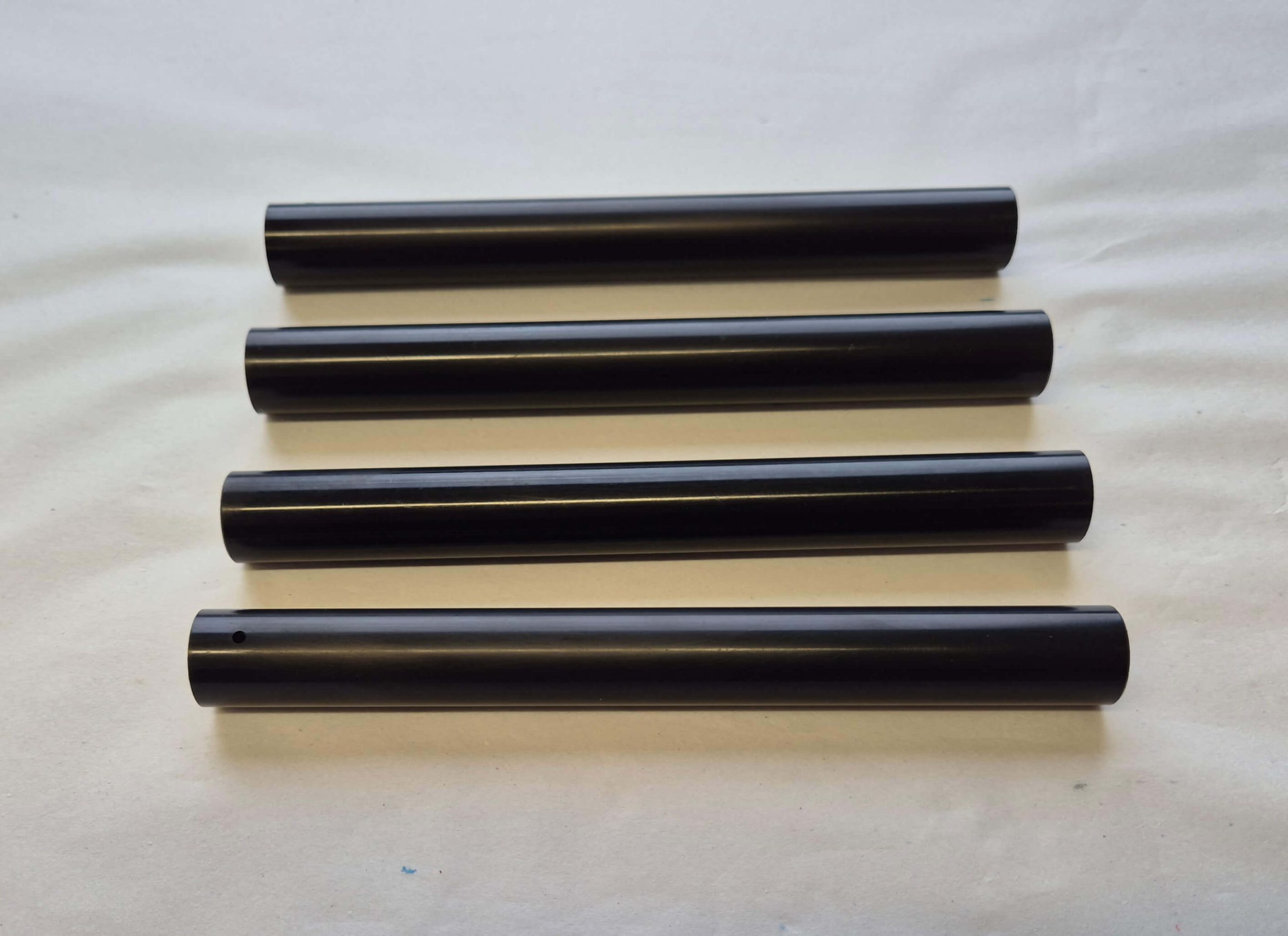

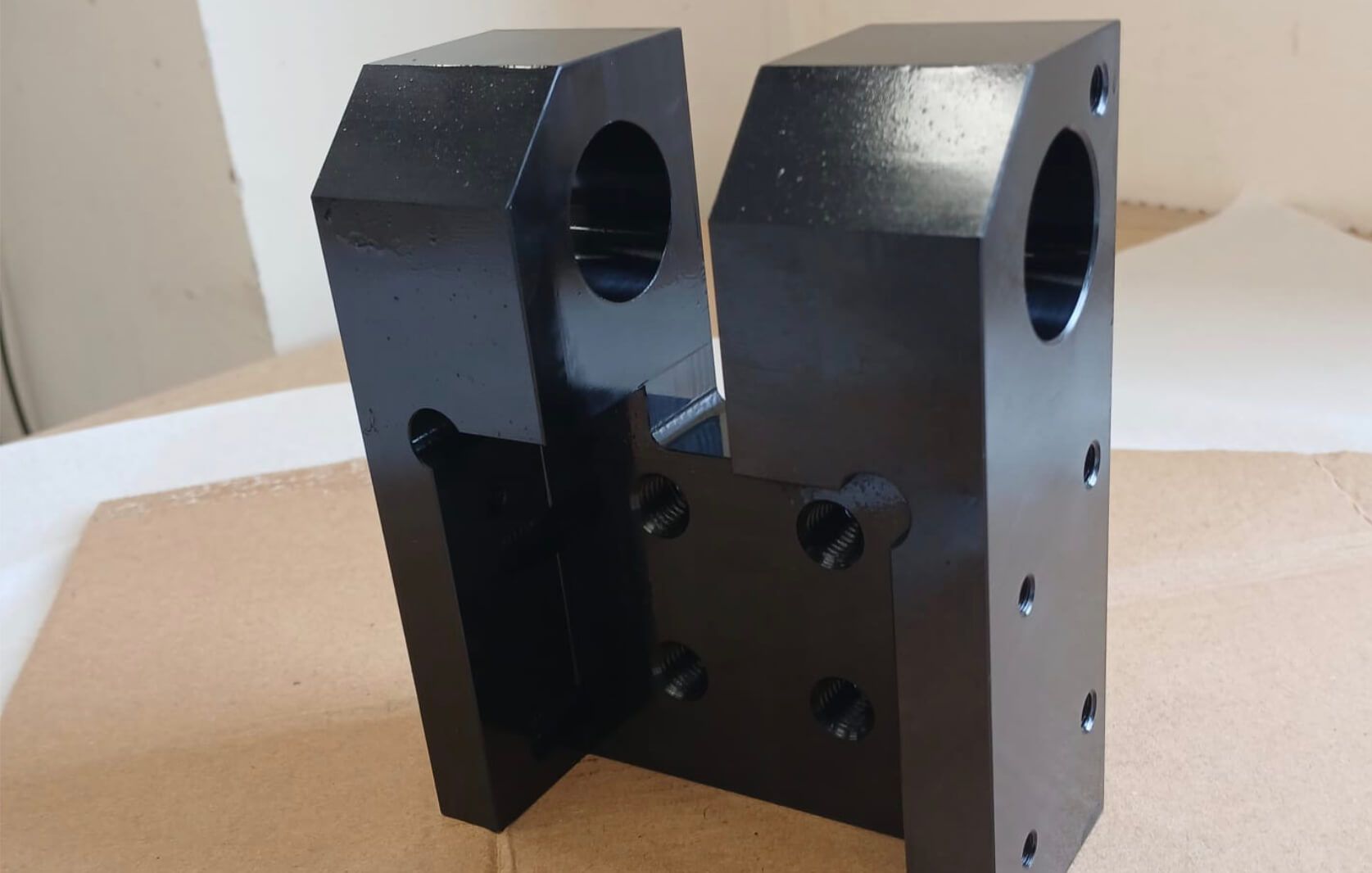

Chemical Blacking (also known as black oxide coating) is a chemical conversion process that produces a durable black finish on ferrous metals such as mild steel, stainless steel and tool steel. It enhances appearance, provides mild corrosion resistance (when sealed) and improves lubricity without affecting dimensions.

Appearance

Creates an attractive, uniform black finish.