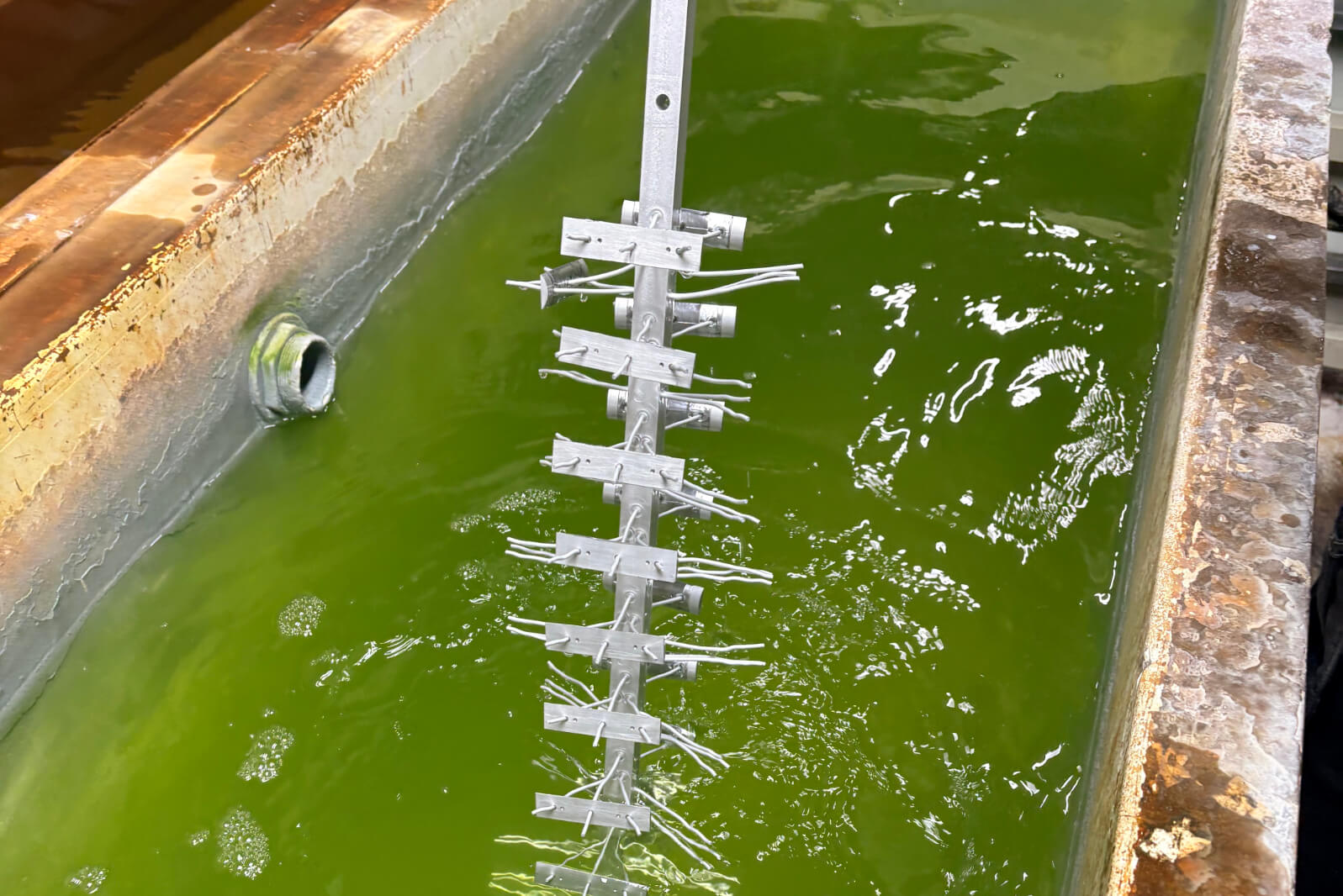

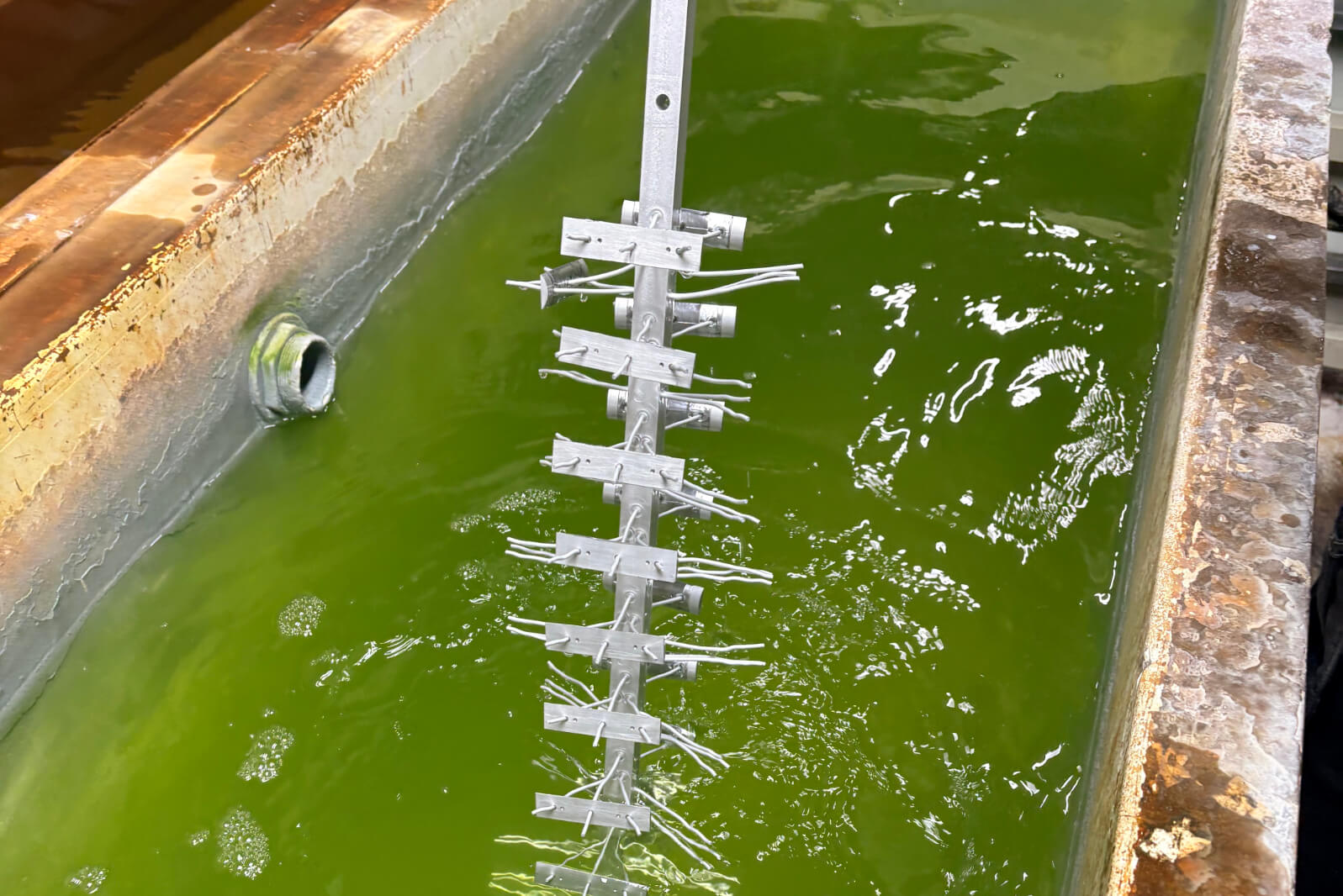

Alocrom or Alodine

A protective chromate conversion coating ideal for aluminium components, offering corrosion resistance and enhanced paint adhesion.

Explore our full range of precision metal finishing processes designed to improve performance, protection, and durability across industries.

We provide a comprehensive range of advanced metal finishing processes designed to meet demanding engineering requirements. Our treatments improve corrosion resistance, durability, conductivity, and overall component performance.

With decades of experience and a commitment to precision, we work closely with customers to ensure every part is processed to the highest standard.

High-quality finishing methods engineered for precision, performance, and durability across demanding industries.

A protective chromate conversion coating ideal for aluminium components, offering corrosion resistance and enhanced paint adhesion.

Blacking copper creates a non-reflective, glare-reducing surface, it is a chemical conversion process that produces a darker finish,. The treatment reacts with the surface to form a stable, dark oxide/sulphide layer without adding measurable thickness, enhancing appearance while providing mild corrosion resistance. It can produce an antique-style finish on copper and copper-based alloys such as brass and bronze.

A reliable coating that protects steel against corrosion, improves durability, and offers a clean, uniform finish for industrial use.

A durable anodic coating applied to aluminium to improve corrosion resistance, wear protection, and surface appearance.

A chemical process that removes contaminants from stainless steel surfaces, improving corrosion resistance and ensuring long-term stability.

A uniform nickel coating applied without electrical current, delivering enhanced hardness, wear resistance, and surface protection.

A chromate conversion coating that provides effective corrosion protection for aluminium components while improving paint adhesion.

A reliable non-chrome conversion coating offering excellent corrosion resistance and a clean, consistent finish on aluminium surfaces.

Chemical Blacking (also known as black oxide coating) is a chemical conversion process that produces a durable black finish on ferrous metals such as mild steel, stainless steel and tool steel. It enhances appearance, provides mild corrosion resistance (when sealed) and improves lubricity without affecting dimensions.